Top 7 Best Robotic Welding Machine this 2025

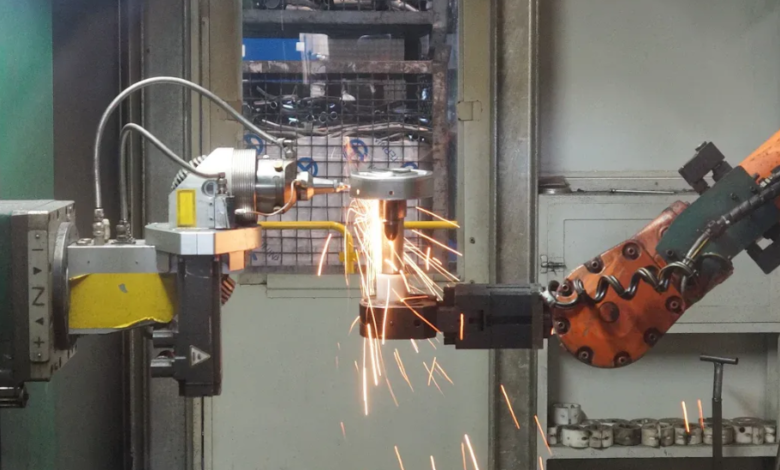

A robotic welding machine is one of the smartest investments manufacturers can make in 2025, thanks to its ability to deliver speed, accuracy, and safety in welding operations. With industries demanding higher productivity and consistent quality, these machines are becoming the go-to solution for businesses of all sizes.

Whether for automotive, construction, or heavy equipment manufacturing, robotic welding offers reliability that manual processes can’t match. In this article, we’ll highlight the Top 7 Best Robotic Welding Machines in 2025 to help you choose the right one for your production needs.

What is a Robotic Welding Machine?

A robotic welding machine is an automated system that uses robotic arms equipped with welding tools to perform precise and consistent welds. These machines can handle various welding methods, such as MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas), and are widely used in industries like automotive, aerospace, and heavy machinery.

How It Works:

- Robotic Arm: It accurately moves the welding tool along the material being welded, following programmed paths to ensure precise and consistent welds.

- Welding Torch: Produces the heat required to melt metals and fuse them during welding.

- Wire Feeder: Feeds the welding wire or filler material to the weld, allowing the robot to create a strong and consistent joint.

- Controller: Acts as the system’s “brain,” controlling the robot’s movements and welding settings.

Robotic welding systems can operate fully automatically, where the robot handles all welding tasks independently, or semi-automatically, where a human loads and unloads parts while the robot performs the welding.

See also: Tea Shops to Tech Startups: How Microloans Support India’s Daily Life

Factors to Consider Before Buying a Robotic Welding Machine

When buying a robotic welding machine, you should consider key factors to ensure it suits your production requirements and budget. This guide will help you make the right choice.

Welding Applications (MIG, TIG, Spot Welding, etc.)

MIG Welding: Fast and great for high-volume production, especially with mild steel.

TIG Welding: Precise and ideal for stainless steel and aluminum, used when strong, clean welds are needed.

Spot Welding: Common in automotive manufacturing for joining sheet metal.

Choose a machine that matches the type of welding your business needs.

- Budget and ROI – Consider the initial cost, operating expenses (maintenance, consumables, energy), and potential savings from higher productivity, reduced labor, and better-quality welds.

- Integration with Existing Production – Ensure the robot can fit in your current workspace, work with existing equipment, and handle different part sizes and shapes.

- Support and Software – Look for manufacturers that provide training, user-friendly software, technical support, and spare parts availability.

- Part Size and Complexity – Ensure the robotic system can handle the shapes and sizes of your components.

- Production Volume and Repeatability – Robots are most effective for high-volume, repeatable tasks.

- Safety – Implement safety measures to protect workers when integrating robots into production lines.

Carefully considering these factors helps businesses select a robotic welding machine that boosts efficiency, maintains quality, and delivers long-term savings.

Top 7 Best Robotic Welding Machines in 2025

These robotic welding machines are designed for different applications, budgets, and production needs:

Top 1: TM Robots

Techman Robots’ AI-powered collaborative welding cobots offer SMEs a versatile and cost-effective automation solution, enhancing productivity and ensuring consistent quality in various industrial applications.

Advantages:

- Easy to program with intuitive interfaces.

- Safe for human-robot collaboration.

- Ideal for small-batch, high-mix production

Use Cases: Automotive parts, electronics assembly, educational applications.

Top 2: Fanuc ArcMate Series

The FANUC Arc Mate Series is engineered for precision and reliability in high-volume manufacturing settings. Its robust design and advanced features ensure consistent weld quality, making it a preferred choice for demanding automotive applications.

Advantages:

- High-speed with excellent repeatability.

- Versatile for arc welding, laser welding, and cutting.

- Proven reliability in demanding environments.

Use Cases: Automotive body welding, chassis assembly, structural components.

Top 3: ABB IRB 1520ID

The ABB IRB 1520ID is a compact, high-precision robotic arc welder designed to meet the needs of small to medium-sized businesses. Its integrated design and advanced features make it ideal for precision welding in confined spaces.

Advantages:

- Space-saving design.

- Low maintenance with reduced downtime.

- High precision and energy-efficient.

Use Cases: Electronics enclosures, medical devices, small-scale manufacturing.

Top 4: KUKA KR 6 R1420

The KUKA KR 6 R1420 is a high-precision 6-axis industrial robot designed for arc welding applications in tight or complex spaces. Its compact design and advanced features make it ideal for tasks requiring accuracy and flexibility.

Advantages:

- Ideal for complex geometries.

- High repeatability and precision.

- Multiple mounting options.

Use Cases: Medical devices, aerospace components, lab automation.

Top 5: Yaskawa Motoman MA1440

The Yaskawa Motoman MA1440 is a flexible and energy-saving 6-axis welding robot. It works accurately and efficiently, making it a great choice for small to medium businesses looking to improve their welding processes.

Advantages:

- Energy-efficient operation.

- Versatile for MIG, TIG, and CMT welding.

- Compact design for flexible integration.

Use Cases: Automotive parts, consumer electronics, general manufacturing.

Top 6: Panasonic TM Welding Robot

The Panasonic TM Series offers welding robots that can work safely alongside humans. They help small to medium businesses work faster and more accurately, especially for tasks like custom or small-batch welding.

Advantages:

- Safe for human-robot collaboration.

- High precision and repeatability.

- User-friendly programming.

Use Cases: Electronics assembly, small-batch production, educational applications.

Top 7: OTC Daihen FD-B6

The OTC Daihen FD-B6 is a small and affordable 6-axis welding robot. It works reliably and has useful features, making it a great choice for small to medium businesses looking for cost-effective automation.

Advantages:

- Cost-effective.

- Integrated utilities for easy setup.

- Compact, slim design.

Use Cases: General manufacturing, educational purposes, small-scale production.

Each welding robot has unique strengths. Choose based on your production needs, budget, and goals to find the best fit for your business.

Benefits of Using a Robotic Welding Machine in 2025

Higher Productivity and Consistency

Robotic welders can work nonstop 24/7, without breaks or fatigue. They follow programmed paths very precisely, producing the same high-quality welds. This consistency reduces mistakes and rework, keeping production on schedule and products reliable.

Cost Savings and Fewer Errors

Robotic welding reduces labor costs, minimizes mistakes, lowers scrap, and improves overall production efficiency.

Improved Workplace Safety

Robots do the dangerous work, like handling heat, sparks, and fumes. This keeps workers safe and reduces strain from repetitive or heavy tasks. It also helps companies follow safety rules more easily.

Reduced Waste and Resource Use

Robots use only the exact amount of welding material needed, cutting down on waste and energy use. Consistent welds also mean less rework, saving both time and resources.

Robotic welding machines make manufacturing faster, safer, and more efficient. They reduce costs, prevent errors, protect workers, and use materials wisely, making them a smart investment for modern factories.