The potential of injection molding robots for human-machine interaction in injection molding operations

Injection molding is a widely used plastic parts manufacturing technology. In recent years, the emergence of injection molding robots has changed how people grasp logistics during injection molding operations, providing new possibilities for human-computer interaction. In this comprehensive guide, we look in-depth at the potential of injection molding robots to enhance collaboration between humans and machines.

Achieve seamless coordination with injection molding robots

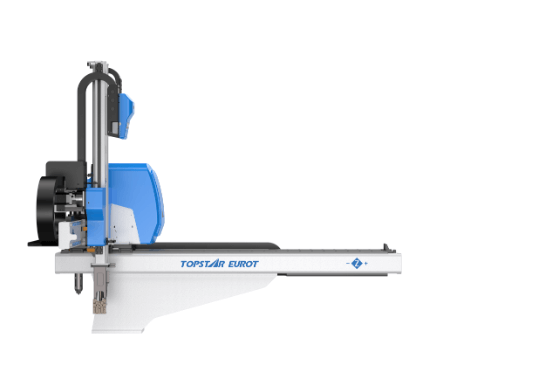

One of the main advantages of injection molding robots is their ability to facilitate seamless coordination and collaboration between human operators and automated systems. Injection molding robots are designed to work alongside humans in shared workspaces, performing repetitive or physically demanding tasks while ensuring the safety of human workers. In injection molding operations, they can assist with tasks such as part handling, conveying, etc., allowing operators to focus on the manufacturing process’s more complex and strategic aspects. This collaborative approach not only improves efficiency but also enhances the overall flexibility and adaptability of production.

Injection molding robot increases efficiency through autonomous operation

Injection molding robot offers the potential for autonomous operation, allowing them to perform tasks with minimal human intervention. Advanced robotic systems with sensors, cameras, and artificial intelligence algorithms can autonomously navigate production environments, identify workpieces, and precisely perform predefined tasks. In injection molding operations, autonomous robots can handle tasks such as mold loading and unloading, material handling and quality control, streamlining production processes, and reducing reliance on human operators. This level of automation increases efficiency and reduces the risk of errors and defects, resulting in higher-quality products.

Injection molding robots provide workers with augmented intelligence

Augmented intelligence, a combination of artificial intelligence and human expertise, is another area where injection molding robots show tremendous potential. By leveraging machine learning algorithms and data analytics, injection molding robots can analyze large amounts of production data in real-time, identify patterns, and provide actionable insights to operators. This enhanced intelligence enables employees to make informed decisions, optimize production processes, and solve problems more efficiently. In addition, injection molding robots provide real-time data insights by integrating manufacturing execution systems (MES) and data analytics platforms. These robots collect and analyze data on production performance, cycle times, defect rates, and machine utilization.

The injection molding robot facilitates remote monitoring

Injection molding robots equipped with remote monitoring capabilities enable manufacturers to oversee the production process from anywhere in the world. By using connected devices and cloud-based platforms, operators can remotely monitor the status of injection molding robots, access real-time data on production metrics, and adjust process parameters as needed. This remote monitoring capability enhances production agility and responsiveness, allowing manufacturers to quickly resolve issues, optimize performance, and ensure continuous operations. In addition, remote access to injection molding robots will enable manufacturers to tap into expertise from around the world further to improve their operations’ efficiency and effectiveness.

Read also Transforming Your Home with Professional Contractors Roofing Renovation

Ensure injection molding safety

Safety is the most critical issue in manufacturing environments, especially in industries such as injection molding that involve heavy machinery and complex processes. Injection Molding Robots = Advanced safety features such as sensors, cameras, and collision detection systems to ensure operator safety and prevent accidents. By implementing safety protocols and compliance standards, manufacturers can create a safe and secure work environment for employees while maximizing the potential of injection molding robots for human-machine interaction. This focus on safety protects workers and increases productivity and efficiency in the long run.

Ultimately

Injection molding robots are reshaping the manufacturing landscape by enabling seamless coordination, increasing efficiency through autonomous operations, providing workers with augmented intelligence, facilitating remote monitoring, and ensuring safety and compliance. By harnessing the power of human-machine collaboration, manufacturers can unlock new possibilities and achieve sustainable growth in the rapidly evolving field of injection molding operations.