Significant role Of Plasma Cutting Machine In Food Engineering

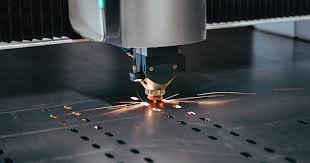

Plasma-cutting machines are linked with the manufacturing sector, and metalworking is determining creative applications beyond ancient manufacturing. One of the rising sectors is food engineering, where cutting-edge technology is being exploited to improve food procedures, preservation, and protection levels.

Plasma machines are mainly used to cut conductive material; they powerfully shape materials up to 50 mm thick and 150 mm in thickness.

Let’s delve into how plasma-cutting machines are transforming the zone of food engineering.

Purification

Plasma-cutting machine sterilize food processing tools, packaging materials, and produce. Plasma creates responsive kinds like ozone and UV radiation, less dangerous bacteria, and molds without employing minimal processes. The friendly environment protects food and extends shelf life by reducing microbial decomposition.

Modify In Packing

Cutting technology permits the accurate change of food packaging material to improve the barrier features, extend the durability, and increase the quality of the product. With fewer holes and surface treatments on the packing films, the machine can exchange gas, regulate moisture and retention, and save the appearance of food.

Activation Process

Plasma cutting can stimulate food surface materials like polymers and biodegradable film to increase compatibility with coverings, adhesives, and printing connections. This increases the combination, lowers contamination chances, and improves product representation and labels in the food market.

Slicing Process

In the food process, cutting machines are used to cut precisely and portion different food products, including cheeses, fruits, and vegetables. Plasma technology’s higher speed and high exactness cutting abilities ensure consistency in portion size, less product wastage, and more production efficiency in food manufacturing.

It can generate the practice surface fabric, design, and mark on the food product for a beautiful brand and original labeling level improvement. Logos, expiration dates, and other information regarding nutrition on food plasma technology provide a wise solution for distinguishing and engaging clients in the food market. There are different machines in the market such as welding machine UAE, laser cutting machine. You can know according to your interest.

Sterilize Packaging

They are cutting machines neutered packed food like pouches, films, and trays. Plasma creates reactive kinds that efficiently deactivate bacteria, fungi, and spores on the packaging surface, ensure antiseptic packages are used, and avoid the contamination of the packaged food during transportation.

Cutting technology improves ventilation in food processing tools, transporters, and storage amenities by removing organic grease and odors. Plasma-generated radicals break contaminants into infection-free products, maintaining healthy conditions and avoiding biosecurity in the environment of food production.

Inactivation Enzyme

The cutting machine can offer sluggish microbes and enzymes in foods like vegetables, fruits, sweets, juices, and dairy time. Handle the exposure to plasma-created responsive species that disturb the enzyme task, save the item quality in the best way, well in service life, and improve the nutritional worth of the foods.

Conclusion

Plasma cutting machines are movable, creating, and modifying the food engineering market, giving many uses that improve the quality, protection of food, and sustainability. With the potential of plasma technology, food manufacturers can improve production procedures, increase item performance, and meet the rising demand of clients for safe, tasteful food items.