The Evolving Role of Hot Melt Technologies in Modern Manufacturing

The Hot Melt Adhesive & Films industry has become a quiet force behind many of the products people use every day. From food packaging and hygiene items to automotive interiors and technical textiles, hot melt solutions help manufacturers achieve speed, consistency, and reliability. As global production systems grow more complex and sustainability expectations rise, this industry continues to adapt through material innovation, process optimization, and application-specific design.

Understanding Hot Melt Adhesives and Films

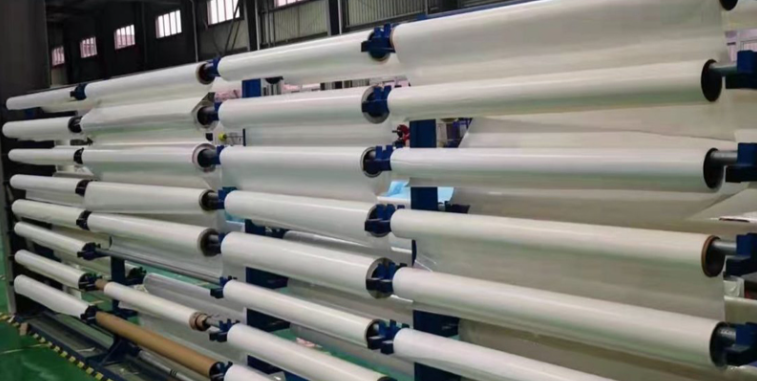

Hot melt adhesives are thermoplastic materials that are heated until they liquefy, applied to a surface, and then solidify as they cool. Hot melt films follow the same bonding principle but are supplied in solid sheet or roll form and activated through heat and pressure. Both options are valued for their clean application, fast bonding, and compatibility with automated production lines.

Because they do not rely on solvents or water evaporation, hot melt systems allow manufacturers to reduce drying time, lower energy use, and maintain high production speeds. These advantages make them especially attractive in industries where efficiency and output consistency are critical.

Key Industries Driving Market Demand

Packaging and Consumer Goods

Packaging remains one of the largest application areas for hot melt adhesives and films. Carton sealing, tray forming, labeling, and flexible packaging all depend on fast-setting bonds that can withstand handling, stacking, and transportation. Hot melt adhesives provide reliable adhesion on a wide variety of substrates, including coated papers, corrugated boards, and plastic films.

As consumer expectations around product safety and presentation increase, packaging producers rely on hot melt technologies to ensure both structural integrity and visual appeal without slowing down production.

Hygiene and Personal Care Products

The hygiene sector places very specific demands on adhesive performance. Products such as baby diapers, adult incontinence items, and feminine hygiene products must balance strength, flexibility, and comfort. An elastic hot melt Elastic hot melt adhesive adhesive is essential in these applications because it allows components to stretch and move naturally with the body while maintaining secure bonding.

This elasticity improves user comfort and product fit, while also supporting high-speed manufacturing processes required to meet global demand for disposable hygiene products.

Automotive and Transportation Applications

In automotive manufacturing, hot melt adhesives and films are widely used for interior components such as headliners, carpets, door panels, and insulation layers. These applications require materials that can handle vibration, temperature changes, and long-term use without degrading.

Hot melt films are particularly useful in this sector because they offer uniform bonding and clean finishes, supporting both functional performance and aesthetic standards. Additionally, lightweight bonding solutions contribute to overall vehicle weight reduction, helping manufacturers meet fuel efficiency and emission targets.

Performance Factors That Influence Adhesive Selection

Speed and Process Integration

One of the most significant advantages of hot melt technologies is their rapid setting time. Unlike liquid adhesives that require extended curing or drying, hot melts solidify almost immediately. This allows manufacturers to move products through assembly lines without interruption, increasing throughput and reducing operational costs.

Quick bonding also enables better integration with automated systems, which are increasingly common across manufacturing sectors.

Strength, Flexibility, and Durability

Different applications require different performance characteristics. Packaging may prioritize high initial tack and fast setting, while textiles and hygiene products demand flexibility and softness. Advances in polymer chemistry allow hot melt formulations to be customized for specific needs, ensuring reliable performance without overengineering.

Durability is another critical factor. Modern hot melt adhesives are designed to resist heat, moisture, and aging, ensuring that bonded products maintain integrity throughout their lifecycle.

Sustainability and Environmental Impact

Cleaner Production Processes

Environmental responsibility has become a core concern for manufacturers worldwide. Hot melt adhesives and films support sustainability goals by being solvent-free, which significantly reduces emissions during application. This not only lowers environmental impact but also improves workplace safety for operators.

Cleaner processes also help companies comply with environmental regulations and meet the sustainability expectations of customers and stakeholders.

Material Efficiency and Waste Reduction

Hot melt films enable precise application, reducing excess adhesive use and minimizing waste. In many cases, they replace mechanical fasteners or multiple bonding layers, simplifying product design and reducing material consumption.

This efficiency supports cost control while also aligning with broader efforts to reduce industrial waste and resource use.

Recycling and End-of-Life Considerations

As recycling systems improve, adhesive compatibility has become increasingly important, particularly in packaging. The industry is responding by developing hot melt formulations that do not interfere with recycling processes. These solutions either separate cleanly or remain neutral during material recovery, supporting circular economy initiatives.

Innovation and Customization in Hot Melt Solutions

Tailored Formulations for Specific Needs

Customization is now a defining trend in the Hot Melt Adhesive & Films industry. Manufacturers can adjust properties such as viscosity, open time, elasticity, and temperature resistance to match specific production requirements. This tailored approach improves performance, reduces downtime, and helps manufacturers adapt quickly to new product designs.

Customized solutions also allow adhesive suppliers to work more closely with end users, creating long-term partnerships rather than one-size-fits-all offerings.

Advances in Application Technology

Material innovation is supported by improvements in application equipment. Modern dispensing and lamination systems offer precise temperature control and accurate placement, even at very high speeds. This precision ensures consistent bonding quality while reducing adhesive consumption and maintenance needs.

Automation and smart controls further enhance process reliability, helping manufacturers maintain consistent output in demanding production environments.

Challenges and Opportunities Ahead

Despite strong growth, the industry faces challenges such as fluctuating raw material prices, evolving regulations, and rising customer expectations. At the same time, these pressures create opportunities for innovation and differentiation.

Companies that invest in research, sustainability, and customer collaboration are better positioned to succeed. By focusing on performance, environmental responsibility, and application-specific solutions, the industry can continue to support the evolving needs of global manufacturing.

Conclusion

The Hot Melt Adhesive & Films industry plays a vital role in modern production systems, enabling speed, reliability, and sustainability across a wide range of applications. From packaging and hygiene products to automotive components and technical textiles, hot melt technologies continue to prove their value. With ongoing innovation in materials, equipment, and recycling compatibility, the industry is well prepared to meet future manufacturing challenges while supporting cleaner and more efficient production worldwide.